Scientists have synthesized a novel fluorinated hybrid material that spontaneously organizes itself into one of the most complex geometric structures known in materials science. The material’s underlying architecture mimics a rare form called a quasi-Johnson solid J₂₈, marking a significant advance in the sophisticated self-assembly of porous frameworks. This achievement in structural control at the molecular level produces a highly specialized environment within the material’s pores, promising new capabilities for industrial separations and chemical processes.

The new porous material integrates fluorine into a “pillar-cage” design, a strategy known to enhance chemical and thermal stability. Its internal structure is what sets it apart, forming a network of cages shaped like a square orthobicupola, the 28th Johnson solid. Johnson solids are a specific set of 92 convex polyhedra made from regular polygon faces, excluding the more common Platonic and Archimedean solids. The discovery represents a leap in creating customized materials where function is dictated by a precisely engineered and complex geometric form.

A Rare Geometric Form

The foundation of the material’s uniqueness lies in its resemblance to a specific mathematical object. The Johnson solids are a finite set of shapes that can be constructed from regular polygonal faces, first fully cataloged by Norman Johnson in 1966. These structures are not as symmetrical as the five Platonic solids but are notable for their complexity and variety. Among them, the J₂₈, or square orthobicupola, is a sophisticated shape composed of 18 faces—eight equilateral triangles and 10 squares—with 16 vertices and 32 edges. It is formed by joining two four-sided cupolas along their octagonal bases.

In the context of this new material, the structure is described as a “quasi-Johnson solid” because it captures the essential connectivity and topology of the J₂₈ polyhedron at the molecular scale. While the faces and edges of the material’s cages are not perfect, rigid polygons, the arrangement of its constituent molecular clusters and organic linkers successfully reproduces the complex geometry of the square orthobicupola. Achieving such a high-order, non-trivial geometry through self-assembly, rather than more common cubic or layered frameworks, is a significant challenge and a notable success in the field of materials design.

Advanced Synthesis and Architecture

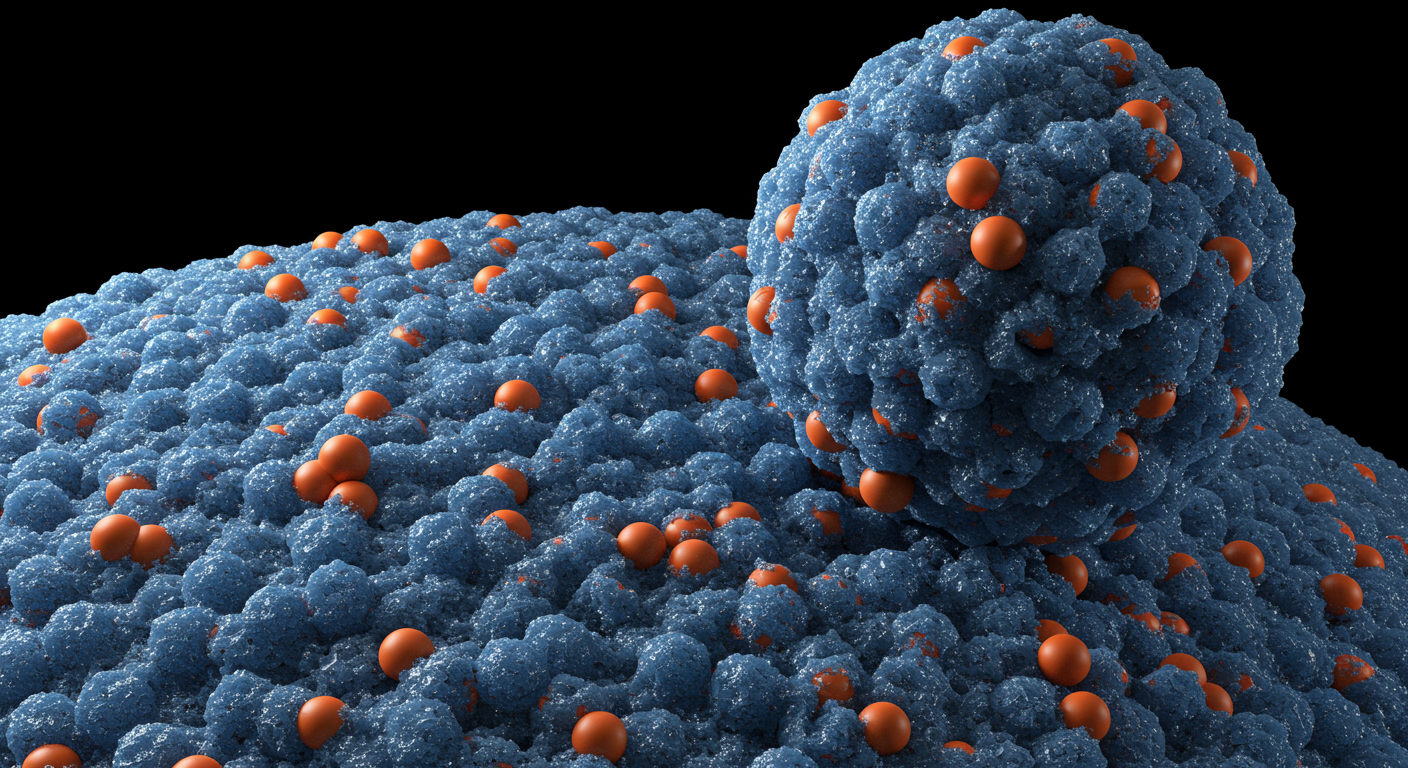

The material is classified as a hybrid porous solid, likely a type of metal-organic framework, or MOF. These materials are constructed from two main components: metal ions or clusters, which act as nodes, and organic molecules, called linkers, that connect these nodes into a repeating framework. The resulting structure is crystalline and contains pores, or cages, that can be tailored for specific tasks. The architecture of the new material is described as a “pillar-cage” system. This design involves the formation of two-dimensional sheets of metal ions and organic linkers, which are then propped apart by other “pillar” linkers to create a robust three-dimensional framework.

A key innovation in this work is the incorporation of fluorine atoms into the organic linkers. Fluorination is a chemical strategy used to impart desirable properties to materials. The strong bonds formed by fluorine atoms increase a material’s thermal stability and resistance to chemical degradation. Furthermore, it creates what are known as “fluorophilic” or “fluorinated” pore surfaces. These surfaces can interact differently with various guest molecules compared to their non-fluorinated counterparts, a property that is highly valuable for selective molecular separation and recognition.

Unique Structural Properties

The combination of the pillar-cage design and the J₂₈ geometry results in a highly specialized porous environment. Unlike simple porous materials with uniform cylindrical or spherical pores, this framework contains intricately shaped cages that mimic the square orthobicupola. This complex shape provides multiple, distinct interaction sites for guest molecules that may enter the pores. The internal surface of these cages, decorated with fluorine atoms, offers tailored binding sites that can selectively capture certain molecules over others based on subtle differences in their size, shape, and chemical properties.

The structure can be conceptualized as an ordered array of nanoscale polyhedra. Each cage effectively acts as a discrete compartment within the larger framework, and these cages are interconnected to form a network of channels. Such a design is distinct from many porous materials where pores are simply voids within a solid matrix. This “cage-in-framework” approach provides exceptional control over the pore environment and is a key factor in the material’s potential for high-performance applications. The successful synthesis of a framework with this specific topology opens the door to targeting other Johnson solids, potentially creating a new family of materials with geometries fine-tuned for advanced functions.

Potential for Advanced Applications

Selective Gas Separations

The most immediate potential application for this new material is in the field of gas separation. The separation of industrially important gas mixtures, such as acetylene from carbon dioxide, is a formidable challenge because the molecules have very similar sizes and physical properties. The fluorinated surfaces within the J₂₈ cages of this material could offer a solution. The fluorine atoms create a polarized environment that can interact more strongly with the slightly acidic hydrogen atoms in acetylene, allowing the material to trap it preferentially while letting other gases like carbon dioxide pass through. This level of selectivity is critical for purifying chemical feedstocks in the polymer industry.

Water Remediation and Environmental Cleanup

Fluorinated porous polymers have also shown significant promise in water remediation. Their hydrophobic nature, enhanced by the presence of fluorine, makes them excellent candidates for separating oils and other organic pollutants from water. Porous materials can also be designed to capture heavy metals or dyes from industrial wastewater. The high surface area and specialized binding sites within the J₂₈ cages could lead to sorbents with higher capacity and greater efficiency than existing materials, potentially leading to more effective and reusable systems for environmental cleanup.

A New Frontier in Material Design

This discovery pushes the boundaries of rational material design. The ability to persuade molecules to self-assemble into a structure as complex as a quasi-J₂₈ solid is a testament to the increasing level of control chemists have over the creation of matter from the bottom up. It suggests that it may be possible to construct materials based on even more intricate polyhedra, including other members of the 92 Johnson solids. This work provides a blueprint for how to combine geometric principles with strategic chemical functionalization—in this case, fluorination—to produce materials with precisely defined properties.

The long-term implications are significant. By mastering the synthesis of materials with complex, predetermined geometries, scientists can develop frameworks optimized for a vast range of tasks. These could include more efficient catalysts that mimic the intricate active sites of enzymes, highly sensitive chemical sensors that recognize specific molecules by shape, and next-generation materials for energy storage and conversion. This research represents not just the creation of a single new material, but a step toward a new paradigm of materials science where complex architecture is no longer a barrier but a target.