Researchers have developed a one-step method that uses rapid heating to recover rare earth elements from electronic waste, offering a more efficient and environmentally friendly alternative to conventional recycling. The technique, known as flash Joule heating, extracts these critical minerals from discarded magnets in seconds without the need for water or toxic acids, addressing major drawbacks of current methods. This breakthrough promises to bolster domestic mineral supplies and promote a circular economy for materials essential to modern technology.

The new process, developed by a team at Rice University, dramatically reduces the energy, emissions, and costs associated with recovering rare earth elements, or REEs. A life cycle assessment and techno-economic analysis found the method reduces energy consumption by 87% and greenhouse gas emissions by 84% compared to traditional hydrometallurgy. Furthermore, it cuts operating costs by 54% and completely eliminates the use of water and acids. By making recycling more economically viable and less hazardous, the innovation could reshape the supply chain for these valuable elements.

A Thermodynamic Approach to Separation

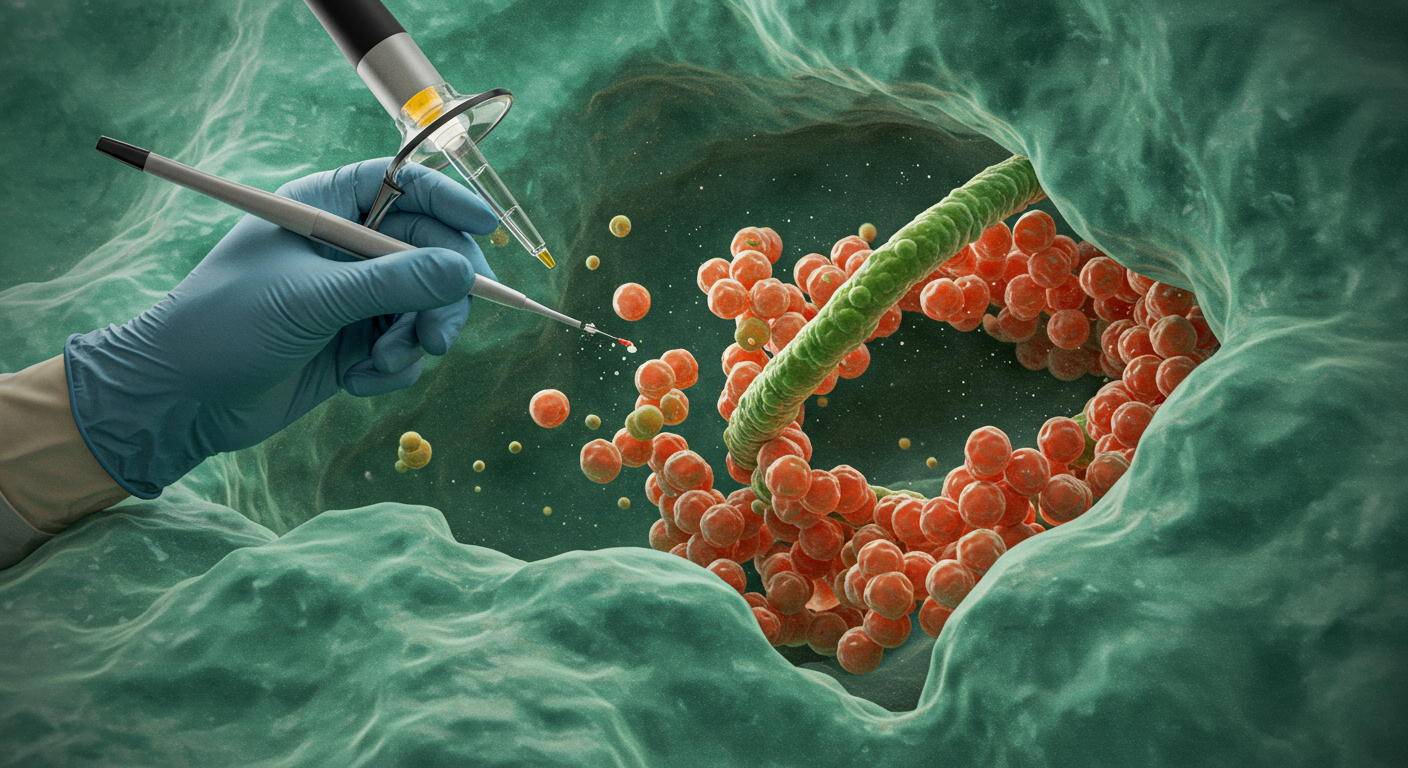

The flash Joule heating method is combined with chlorine gas to selectively separate rare earth elements from other metals commonly found in magnets. The process rapidly elevates the material’s temperature by thousands of degrees within milliseconds. This intense heat, in the presence of chlorine, leverages the different thermodynamic properties of the elements within the magnet waste.

Exploiting Chemical Reactivity

The core of the technique relies on the varying Gibbs free energy and boiling points of the metal chlorides. Elements like iron and cobalt react with chlorine at high temperatures to form volatile chlorides, which vaporize and separate from the solid rare earth elements. This leaves behind a concentrated residue of REE oxides with high purity. Researchers tested the process on waste from both neodymium-iron-boron and samarium-cobalt magnets, the two most common types of permanent magnets.

Efficiency and Purity Gains

In laboratory experiments, the flash Joule heating method demonstrated remarkable effectiveness, achieving over 90% purity and yield for the recovered rare earth elements in a single step. This level of efficiency is a significant improvement over traditional hydrometallurgical and pyrometallurgical methods, which are often multi-stage, energy-intensive, and produce substantial waste streams. The ability to extract REEs so cleanly and quickly is a key advantage of the new technology.

Eliminating Hazardous Waste

A primary benefit of this novel approach is the complete elimination of liquid waste. Conventional hydrometallurgy relies heavily on strong acids to dissolve the magnet material, a process that generates large volumes of toxic aqueous waste that is difficult and costly to treat. The flash Joule heating technique avoids this entirely by using a gas-phase reaction to achieve separation, representing a significant environmental improvement. The only byproducts are the vaporized metal chlorides, which can be collected and potentially repurposed.

Economic and Strategic Implications

The economic advantages of the new method are substantial. By reducing energy use, eliminating the need for expensive chemical reagents like acids, and simplifying the overall process, operating costs are cut by more than half compared to current standards. This improved cost-effectiveness could make e-waste recycling a more attractive commercial venture, encouraging wider adoption and helping to mitigate supply chain vulnerabilities for rare earth elements.

Decentralized Recycling Potential

The technology’s design also allows for scalability and decentralization. The simplicity and speed of the flash Joule heating units mean they could be deployed in small or large facilities located near sources of electronic waste collection. This would reduce the need to transport hazardous e-waste over long distances, further cutting costs and environmental impact. Such a distributed network of recycling centers could enhance the resilience of domestic supply chains for these critical materials.

Addressing a Critical Need

Rare earth elements are indispensable components in a wide array of modern technologies, including smartphones, electric vehicles, wind turbines, and advanced defense systems. However, their supply is concentrated in a few countries, creating geopolitical and economic risks. At the same time, massive amounts of these valuable elements are lost in discarded electronics. An estimated 130,000 to 150,000 metric tons of neodymium-iron-boron magnets are produced annually, with a large portion discarded as manufacturing scrap or ending up in landfills.

Developing efficient and sustainable methods for recovering REEs from this growing stream of e-waste is a critical challenge. The flash Joule heating process offers a promising pathway to not only alleviate environmental burdens associated with mining and waste but also to establish a more secure and circular supply of materials vital to the global economy and green energy transition. The research was detailed in a study published in the *Proceedings of the National Academy of Sciences*.