Researchers have developed an electrochemical system that converts a single plant-based compound into two different valuable chemicals simultaneously, a process that could make the production of biofuels and other bio-based products more efficient and cost-effective. The system uses a flow reactor to both oxidize and reduce a lignin-derived compound, creating separate streams of useful products with minimal energy loss and high selectivity.

This innovative approach tackles a major challenge in biorefining, where complex plant materials like lignin are often underutilized or burned for low-value heat. By creating a paired electrolysis system, scientists can now upgrade a common lignin byproduct, guaiacol, into two distinct and commercially relevant molecules at the same time. One product, a redox-active molecule, is valuable for advanced battery technologies, while the other, a precursor for pharmaceuticals and polymers, is created in a separate stream. This dual-synthesis method represents a significant step toward more sustainable and economically viable biorefineries.

Paired Electrolysis for Biomass Conversion

The core of the new technology is a process called paired electrolysis, which leverages both halves of an electrochemical reaction. In a typical electrochemical cell, a power source drives a reaction that has two parts: oxidation at the anode and reduction at the cathode. Often, only one of these reactions produces a desired chemical, while the other is simply a necessary but unproductive part of the circuit. The research team, however, designed a system where both the anodic and cathodic reactions create valuable products from the same starting material.

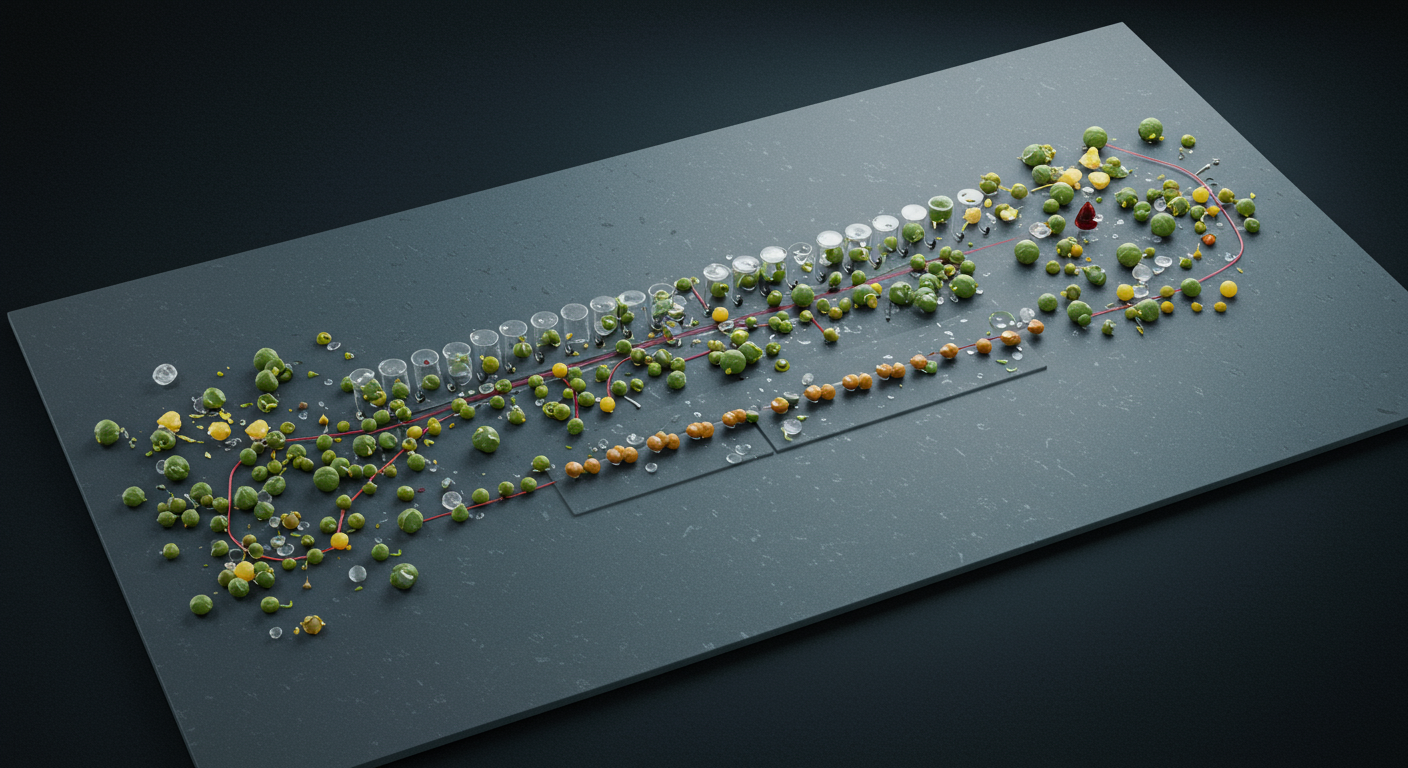

In this specific application, guaiacol, a compound readily available from the breakdown of lignin, is fed into an electrochemical flow reactor. At the anode, the guaiacol molecule is oxidized, a process that removes electrons and results in the formation of a valuable polymer. Simultaneously, at the cathode, the same guaiacol is reduced, a process that adds electrons, to create a different chemical, which can be used as a fuel additive or a precursor for other chemicals. This simultaneous synthesis in one reactor significantly improves the overall efficiency and atom economy of the process, reducing waste and maximizing the value extracted from the initial biomass.

Design of the Flow Reactor

The system was specifically engineered as a continuous flow reactor, which offers several advantages over traditional batch reactors. In a flow system, reactants are constantly pumped into the reactor, and products are continuously removed. This allows for more precise control over reaction conditions, such as voltage, temperature, and residence time. This level of control is crucial for achieving high selectivity, meaning the process overwhelmingly produces the desired chemicals with minimal formation of unwanted byproducts. The continuous nature also makes the process more scalable for industrial applications, as it can operate for extended periods without interruption.

Selective Production of Valuable Chemicals

A key achievement of this research is the high degree of selectivity for the two different products. By carefully tuning the electrochemical conditions and the design of the reactor, the scientists were able to steer the reactions toward the desired outcomes with remarkable precision. The oxidation reaction at the anode primarily produced a conductive polymer, a material of interest for energy storage applications like redox flow batteries. These batteries are a promising technology for large-scale grid energy storage, which is essential for integrating renewable energy sources like solar and wind power.

At the cathode, the reduction of guaiacol yielded a deoxygenated product that can serve as a building block for various high-value chemicals. The removal of oxygen from biomass-derived molecules is a critical step in converting them into energy-dense fuels and commodity chemicals that are compatible with existing infrastructure. The ability to produce both a polymer for batteries and a chemical precursor from one feedstock in a single pass highlights the economic potential of this electrochemical upgrading strategy.

Implications for Biorefineries

The findings have significant implications for the future of biorefining. Lignin is one of the most abundant organic polymers on Earth, making up a significant portion of wood and other plant biomass. However, its complex and irregular structure makes it difficult to break down into uniform, valuable products. Consequently, lignin is often treated as a low-value waste product in the pulp and paper industry and in cellulosic ethanol plants, where it is typically burned to generate heat and power. This new electrochemical approach provides a pathway to upcycle lignin-derived compounds into high-value products, potentially creating new revenue streams for biorefineries.

By making the conversion of biomass more profitable, this technology could accelerate the transition away from a petroleum-based economy. The production of fuels, chemicals, and materials from renewable plant sources is a cornerstone of a more sustainable industrial ecosystem. This electrochemical system demonstrates a way to do so more efficiently, reducing waste and energy consumption compared to conventional thermochemical methods, which often require high temperatures and pressures.

Sustainability and Economic Viability

The sustainability of the process is enhanced by its energy efficiency. The paired electrolysis design makes excellent use of the electrical energy supplied to the system, as both the anodic and cathodic processes contribute to product formation. This contrasts with many electrochemical processes where the reaction at one electrode is essentially wasted. Furthermore, the reactions occur at or near room temperature and pressure, further reducing the energy footprint. From an economic standpoint, the ability to generate two valuable products from a single, low-cost feedstock significantly strengthens the business case for this type of biorefinery technology. The dual-stream output increases the potential revenue per unit of biomass processed, which is a critical factor in the competitiveness of bio-based products against their fossil fuel-derived counterparts.

Challenges and Future Directions

While the laboratory-scale results are promising, scaling up this electrochemical system for industrial production presents several challenges. One major hurdle is the long-term stability and durability of the electrodes under continuous operation. The materials used for the anode and cathode must be able to withstand the reactive chemical environment for extended periods without degrading or losing their catalytic activity. Further research will be needed to develop robust and cost-effective electrode materials suitable for large-scale applications.

Another area for future work is expanding the scope of the process to other biomass-derived feedstocks. While guaiacol is a representative model compound for lignin, real-world lignin streams contain a complex mixture of different aromatic compounds. Adapting the electrochemical system to handle these more complex mixtures and selectively convert them into desired products will be a critical next step. The researchers also aim to further optimize the reactor design and operating conditions to maximize product yields and energy efficiency, pushing the technology closer to commercial readiness and contributing to a more circular and sustainable economy.