A team of researchers has developed an exceptionally compact and powerful excimer laser, with a size comparable to a standard thermos bottle. This significant reduction in size was achieved by replacing the bulky and noisy mechanical gas pumps found in traditional systems with a novel electrohydrodynamics (EHD) pump, a change that also eliminates vibrations and opens up new possibilities for portable applications. The new design not only shrinks the hardware but also incorporates a sophisticated machine learning model to predict and control the laser’s complex energy dynamics, ensuring stable and powerful performance.

Excimer lasers are crucial sources of deep ultraviolet light, valued in fields ranging from scientific research and industrial material processing to environmental monitoring. However, their practical use has been hampered by their reliance on mechanical pumps to circulate the gas medium required for laser operation. These conventional pumps make the laser systems large, loud, and prone to vibrations, which restricts their deployment in sensitive environments or on mobile platforms such as drones and marine vehicles. The development of a silent, compact, and stable alternative addresses these fundamental limitations, paving the way for high-performance excimer lasers that can operate effectively in the field.

Overcoming Conventional Laser Limitations

The core challenge in creating portable excimer lasers has been their dependence on mechanical gas circulation systems. These systems are essential for refreshing the gas medium within the laser cavity, a process necessary for stable and continuous operation. However, the physical size, noise, and vibrations produced by these pumps have historically confined powerful excimer lasers to laboratory and industrial settings. Such limitations have made it difficult to use them for applications requiring mobility and precision, including airborne environmental sensing or exploration in remote marine environments.

The research team, led by Prof. LIANG Xu at the Hefei Institutes of Physical Science, Chinese Academy of Sciences, directly targeted this issue. Their goal was to engineer a system that could circulate the laser’s gas medium without the drawbacks of moving parts. By eliminating the mechanical pump, they could drastically reduce the overall footprint and operational noise of the laser, making it suitable for a much broader range of applications where portability is a key requirement. The result of their work is an ultra-compact laser with a system volume measuring just Ø130 mm × 300 mm.

The Electrohydrodynamics Pump Solution

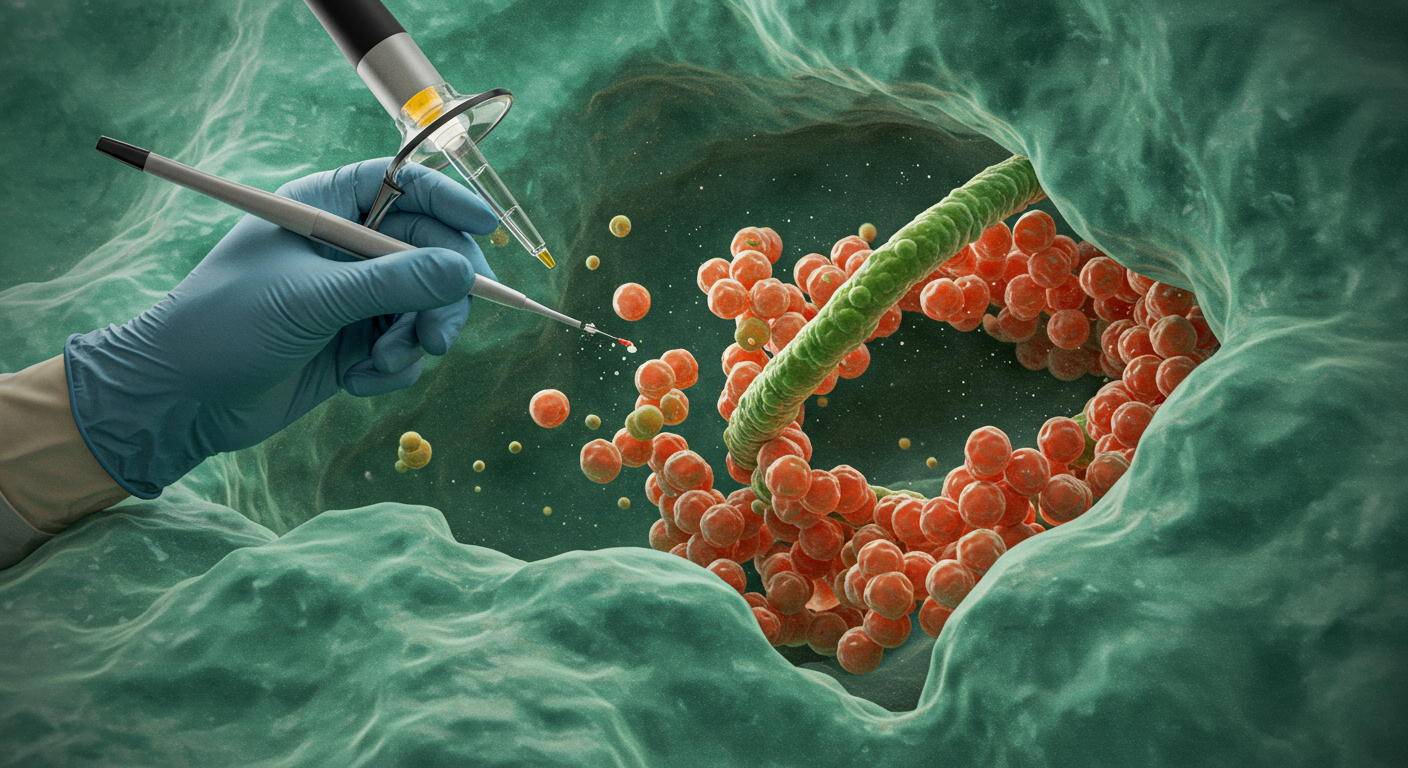

The key innovation in this new laser is the use of a multi-needle corona discharge Electrohydrodynamics (EHD) pump. Unlike a mechanical pump, the EHD system has no moving parts. It works by applying a high voltage to a series of sharp needles, which ionizes the surrounding gas. This creates an ion wind that effectively circulates the gas medium through the laser cavity. This silent and vibration-free method of circulation allowed the researchers to build a much smaller and more robust laser system.

To verify the effectiveness of the EHD pump, the team developed a specialized diagnostic tool called non-invasive point schlieren velocimetry. This technique allowed them to measure the speed of the gas flow inside the laser without disturbing its operation. Their measurements confirmed a gas flow velocity of 1.27 m/s, which is sufficient for high-repetition-rate performance. At an operating frequency of 100 Hz, the system achieved a gas refresh rate of 6.35, demonstrating that the EHD pump could effectively replace its mechanical counterparts.

Performance and Stability

The newly designed ultra-compact excimer laser delivers impressive performance metrics. It achieves a pulse energy exceeding 2 millijoules while maintaining a high degree of energy stability. The team reported a relative standard deviation as low as 1%, indicating consistent and reliable laser output. This level of stability is critical for applications that demand precise and repeatable laser pulses, such as in scientific instrumentation and industrial micro-machining.

During testing, the researchers observed an unexpected phenomenon they described as an “explosive transition behavior” in the laser’s pulse energy under specific operating conditions. Intrigued by this, they conducted a detailed analysis of the complex photochemical reactions within the XeCl (xenon chloride) excimer network. Their investigation revealed that this abrupt shift in performance was linked to a threshold-driven burst in photon flux, providing new insights into the microscopic physics governing the laser’s macroscopic behavior.

Machine Learning for Predictive Control

To better understand and control the laser’s performance, especially the observed energy transitions, the researchers developed an interpretable machine learning model. This computational tool can accurately predict these energy shifts across a wide range of operating parameters. By inputting data on gas pressure, voltage, and other variables, the model can anticipate how the laser will behave, offering a powerful method for optimizing and controlling the system. [cite:al]

The development of this predictive model is a significant step forward for the practical application of these compact lasers. It provides a valuable tool for ensuring stable operation and for fine-tuning the laser’s output for specific tasks. This synergy of a novel hardware design with advanced machine learning showcases a new direction for the development of sophisticated, field-deployable laser systems. The research, which was published in the journal *APL Photonics*, lays the groundwork for the next generation of portable deep ultraviolet light sources.