Chemists have developed a novel method to construct complex organic molecules using common air and light, creating a sustainable pathway for producing compounds vital to the development of future medicines. This breakthrough in green chemistry, led by researchers at The University of Osaka, bypasses the need for harsh chemicals and energy-intensive conditions that have long been standard in the pharmaceutical and chemical industries, significantly reducing waste and environmental impact.

The new technique represents a major advance in a field known as catalytic asymmetric synthesis, which is crucial for creating therapeutic drugs. At its core, the process uses a specialized vanadium catalyst that, when activated by the energy from simple LED lights, can skillfully stitch together simple molecules to form intricate, three-dimensional structures. Researchers successfully demonstrated the method by producing axially chiral bianthrols, specifically a valuable compound known as NOBIN, a foundational component in many pharmaceutical agents. This approach not only offers a cleaner, more efficient way to make known drugs but also opens the door to discovering new medicinal compounds.

A Greener Synthetic Pathway

Traditional chemical synthesis often relies on a sequence of complex steps, each requiring specific and sometimes hazardous reagents, high temperatures, and significant energy input. This multi-stage process generates a substantial amount of chemical waste, posing environmental challenges. The new method streamlines production by establishing what scientists call a cooperative catalysis system. It marks a departure from conventional practices by creating a single, efficient reaction cascade that builds complex products from simple starting materials in one go.

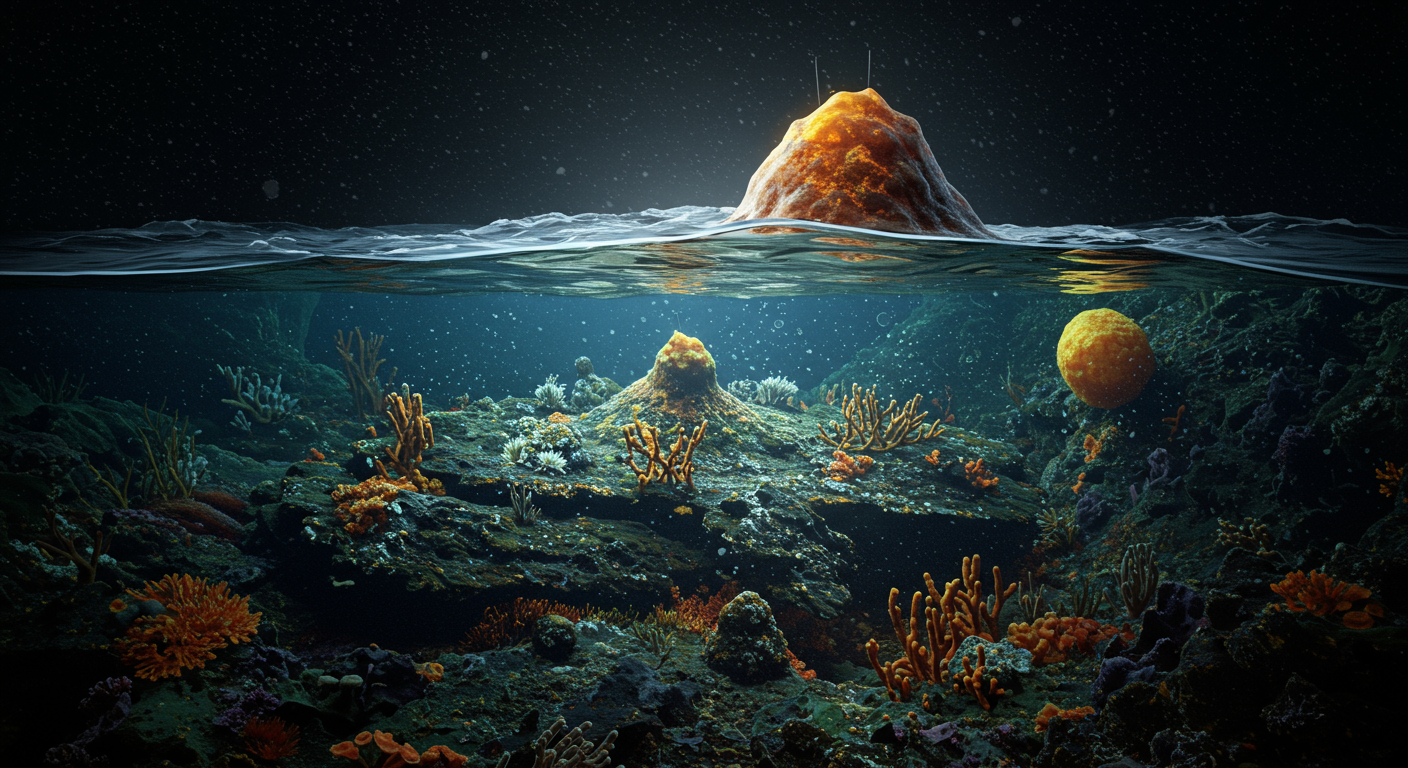

The elegance of the process lies in its ability to use oxygen from the air as a natural oxidizing agent. In the reaction, the vanadium-based catalyst absorbs energy from visible light, which triggers the formation of reactive intermediates. These intermediates then selectively couple to form the desired molecule. By harnessing oxygen and light, two of the most abundant resources on the planet, the researchers have created a production model that is both cost-effective and environmentally benign. This approach dramatically minimizes the carbon footprint associated with manufacturing the building blocks of essential medicines.

Mimicking Nature’s Efficiency

Inspired by Photosynthesis

The innovative method draws conceptual inspiration from photosynthesis, the process plants use to convert sunlight into chemical energy. In nature, chlorophyll captures photons from the sun to drive the transformation of water and carbon dioxide into glucose. Similarly, this chemical process uses a photocatalyst to absorb light energy and use it to drive a difficult chemical reaction under mild conditions. This field, known as photoredox catalysis, has gained significant attention for its ability to enable chemical transformations that were previously impractical or required extreme measures to achieve.

The Role of the Vanadium Catalyst

The success of the reaction hinges on the uniquely designed vanadium catalyst. Vanadium is a relatively abundant and low-cost metal, making it an attractive alternative to the precious metals, like palladium or rhodium, often used in catalysis. The specific catalyst developed by the Osaka team is engineered to perform asymmetrically, meaning it can control the spatial arrangement, or chirality, of the atoms in the new molecule. This is exceptionally important in drug development, as different three-dimensional arrangements of the same molecule can have vastly different biological effects, with one version being therapeutic while another could be ineffective or even harmful.

Producing High-Value Molecules

The primary achievement highlighted by the research team was the synthesis of NOBIN and its derivatives. NOBIN, which stands for 2-amino-2′-hydroxy-1,1′-binaphthyl, is a chiral ligand and catalyst that is itself a critical tool in the synthesis of other complex molecules, particularly active pharmaceutical ingredients. Its unique structure makes it highly effective in guiding reactions to produce a specific chiral version of a target drug molecule.

By demonstrating that their light-powered method can produce these high-value compounds efficiently, the researchers have validated its practical potential. The ability to generate NOBIN derivatives easily and sustainably could lower the cost and environmental toll of producing a wide range of medicines, from anti-inflammatory drugs to treatments for neurological disorders. Professor Shinobu Takizawa, the lead author of the study, emphasized that this process paves the way for synthesizing not only existing drug candidates but also entirely new and more complex molecules that were previously too difficult to create.

Future of Pharmaceutical Manufacturing

The implications of this work extend far beyond the laboratory. The development of a clean, light-driven manufacturing process offers a roadmap for a new generation of pharmaceutical production. As the industry faces increasing pressure to adopt more sustainable practices, technologies that reduce waste, energy consumption, and the use of hazardous materials are becoming critical. This method provides a powerful example of how green chemistry principles can be translated into practical, high-impact applications.

Furthermore, the accessibility of the core components—air, light, and an inexpensive metal catalyst—could help democratize the production of vital chemical feedstocks. The research team is continuing to explore the versatility of their vanadium catalyst, with the goal of expanding the library of molecules it can produce. The ultimate vision is a future where essential medicines are manufactured in a way that is not only efficient and precise but also harmonious with the environment, powered by little more than light and air.